- Overview

- Recommended Products

WJ High Pressure Hydraulic Hose — Custom Pressure 330–2000 bar

The WJ high pressure hydraulic hose is built for demanding applications where reliability, safety and long service life are essential. Designed to operate in extreme pressures from 330 bar up to 2000 bar, this hose gives you the strength and performance needed for heavy industrial, mining, construction, offshore and hydraulic test systems. WJ combines proven materials, precise construction and strict quality control to deliver a hose that stands up to high fluid pressures, frequent cycling and harsh environments

Construction and materials

WJ high pressure hydraulic hose features a multi-layer construction engineered for maximum strength and durability. The inner tube is made from smooth, oil-resistant synthetic rubber that is compatible with a wide range of hydraulic fluids. Surrounding the tube are multiple layers of high-tensile steel wire braids or spiraled steel reinforcement, depending on the pressure rating. This reinforcement is carefully wound to provide uniform strength and resist kinking under load. The outer cover is a rugged rubber compound formulated for abrasion resistance, ozone resistance and protection against weather, oil and chemicals. Each layer is bonded together under controlled conditions to ensure consistent performance and leak-free service

Pressure ratings and options

WJ offers a full range of custom pressure ratings from 330 bar up to 2000 bar to match your system requirements. Lower-pressure models use braided reinforcement for flexibility and ease of installation, while high-pressure variants use multiple spiral steel layers to safely contain extreme pressures. Each hose is rated for both working pressure and burst pressure with a safety factor appropriate for hydraulic systems. Custom pressure options let you choose the exact rating you need so you don’t over-specify or underperform. WJ can supply hoses tailored for static high-pressure use, dynamic high-cycle applications or intermittent pressure spikes

Temperature range and fluid compatibility

WJ hydraulic hoses are formulated to operate across a wide temperature range to suit indoor and outdoor applications. The materials are selected to retain flexibility in cold environments and resist softening at elevated temperatures. The inner tube is compatible with common hydraulic fluids including mineral oils, some synthetic fluids and certain water-glycol fluids. For specialized fluids or extreme temperature ranges, WJ provides custom compound options and compatibility testing to ensure safe, long-lasting performance

Flexibility and handling

Despite their high pressure capability, WJ hoses are engineered for practical handling. Lower pressure and medium-pressure variants offer excellent bend radius and flexibility for tight routing in machinery and mobile equipment. Higher-pressure spiral-reinforced hoses maintain reasonable flexibility while delivering the necessary stiffness required at extreme pressures. WJ also offers a range of end fittings and coupling options that are crimped or swaged to ensure secure connections and ease of installation. Standard and custom lengths are available to minimize field joins and potential leak points

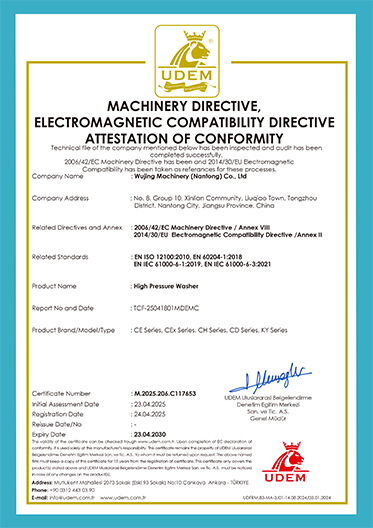

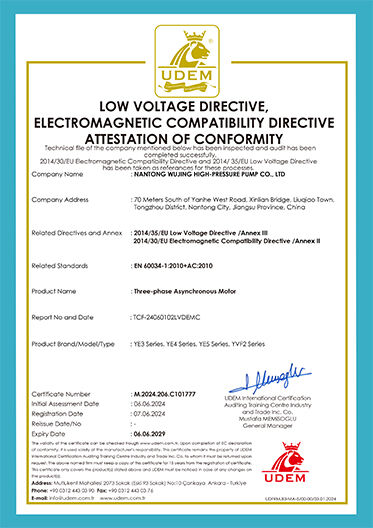

Safety and standards

WJ places a high priority on safety. Each hydraulic hose is manufactured using strict quality control procedures and inspected to meet industry standards. Burst testing, dimensional checks and material inspections are performed to verify performance. WJ hoses can be supplied to meet common international standards used in hydraulic systems, and documentation, test certificates or traceability records are available on request. The hoses are designed with appropriate safety margins so that operators can trust them under demanding conditions

Durability and resistance

The durable outer cover resists abrasion from repeated contact and rough surfaces, extending hose life in the field. Ozone and weather resistance protects the hose when used outdoors, while oil- and chemical-resistant compounds guard against common contaminants that would otherwise degrade lesser hoses. The steel reinforcement resists fatigue and maintains integrity under high-cycle conditions. Overall, WJ hydraulic hoses are engineered for long-term reliability so you can reduce downtime and maintenance costs

Customization and fittings

WJ understands that no two hydraulic systems are exactly the same. That’s why custom lengths, pressure ratings and fitting types are offered to match specific system needs. Choose from a variety of fittings including straight, elbow and swivel configurations, in different thread types such as BSP, NPT, JIC or metric sizes. Custom crimping and marking services are available so hoses arrive ready for installation with clear pressure ratings, part numbers and identification. For specialized applications, WJ can work with customers to create hoses with enhanced chemical resistance, longer life covers or modified bend characteristics

Applications

WJ high pressure hydraulic hose is suitable for a wide range of heavy-duty applications:

- Hydraulic presses and test benches that require very high pressures

- Mobile hydraulic equipment in construction and mining

- Offshore and marine hydraulic systems exposed to salt air and rough conditions

- Industrial machinery and metalworking equipment with high-cycle pressure demands

- High-pressure cleaning systems, jacking systems and hydraulic tensioning tools

- Custom hydraulic assemblies and factory automation systems

Installation and maintenance

Proper installation and maintenance are key to maximizing hose service life. WJ hoses are easy to install when routed to avoid sharp bends and twisting. Use proper clamps and supports to prevent abrasion and chafing. Inspect hose assemblies regularly for signs of wear, external damage or connection leaks. Replace hoses that show cracks, bulges or significant outer cover damage. WJ can provide guidance on best practices for installation, storage and scheduled inspection intervals to help maintain system integrity

Why choose WJ

- Trusted brand focused on high-pressure hydraulic performance

- Wide pressure range from 330 to 2000 bar covering many industries

- Robust construction with steel wire braid or spiral reinforcement

- Durable covers for abrasion, ozone and oil resistance

- Custom options for fittings, lengths and special materials

- Thorough testing and quality control for safe, reliable operation

The WJ high pressure hydraulic hose delivers dependable performance in the toughest hydraulic environments. Built with quality materials, engineered reinforcement and flexible customization options, it meets the needs of systems requiring pressures from 330 up to 2000 bar. Whether for mobile equipment, industrial presses or specialized hydraulic tooling, WJ hoses are a reliable choice to keep your operations running safely and efficiently

Company Profile

Wujing Machinery (Nantong) Co., Ltd

Customization