It's important to choose the correct high-pressure pump that best fits your flow rate requirements and is trustworthy in a manufacturing process. WJ camp pump is used in a series of high performance pumps with different flow rates. Learning how to select flow rate effectively can not only help you maximize efficiency, but also enables you to reach desired results during use, even with high-pressure pumps.

Selecting the Reasonable Flow Rate:

When choosing a high pressure pump, sometimes there are different factors to consider than when choosing the pump for your house. The only really important number is the flow. By flow, I mean how much fluid you can High pressure pump in a given amount of time. To select the proper flow rate for your system you will first need to know the system flow rate requirements. This depends on the size of the piping system, distance the liquid must travel, and pressure amount desired at point of use.

Also important to keep in mind is the nature of the fluid that is being pumped all fluids are not created equal, and they certainly do not have the same viscosities or flow characteristics which might affect flow rate demands. For instance, the pump may need to be of lower flow rate for pumping a high viscosity fluid in order to operate properly. One also needs to allow for changes that may happen in flow rate from these during service, including demand fluctuations or differences in system conditions.

Best Flow Rate with High-Pressure Pumps:

The optimal flow rate for high-pressure pumps can change due to application and system requirements. Higher flow capacity is, on the other hand, generally preferred in applications where large amounts of fluid are to be conveyed over large distances or at high under pressures. These may be operations such as water jetting, pressure testing or industrial cleaning where large amounts of liquid have to be delivered at high rates.

It's necessary to find and adjust the optimal flow of Stainless Steel Plunger Pump which directly affects the delivery output as well as the efficiency. Selecting a flow rate that is not ideal can lead to inefficiency, excess energy consumption, shortened pump life and more. Working with a trusted supplier such as WJ, you are able to discover the right flow rate for your application requirements and guarantee dependable performance and cost-efficiency for your industrial processes.

Factors to Consider When Choosing a High-Pressure Pump

When choosing a high pressure pump for your needs, the task can be a daunting one. One the first things to consider is how fast a flow you need. That is, the flow rate is the volume of liquid that can be moved by the pump in a given time. It’s important to get the pump flow rate that is right for your needs, whether you’re moving a high volume of liquid quickly or are looking for a slower pace with more precision.

Pressure rating of the pump is also another factor to take into account. High pressure pumps are made to pump liquids containing lots of solids and compressors can be found in a number of different styles, including the ones that are leakage free for quite some applications. You will also need to consider what the pump is made from. Certain liquids may be corrosive or abrasive in which case you will want a pump constructed out of tough materials that won't corrode.

How to Make the Most of Your High-Pressure Pump Investment

After you’ve chosen the right high-pressure pump for your whitewater rafting needs, it’s important to make sure you maximize your investment. Weekly, consistent care will make sure your pump is running as well as it should. Since prevention is better than cure, you should also maintain the generator following the manufacturer's guidelines and address any required repairs to avoid expensive ills.

Top Reasons to Buy High Pressure Pumps

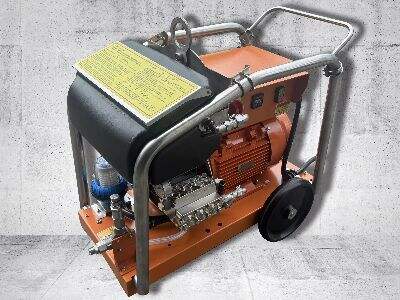

There are a few great reasons to consider pressure machine pump for your business, or personal use. High-pressure pumps are very versatile and can be applied in a whole host of different situations, from industrial to cleaning. They are critical in processes that involve pumping liquids at high pressure including power washing, water jet cutting and oil and gas production.

Our high-pressure pumps, which are the heart of the systems are also highly efficient, and you can accomplish your jobs quickly and effectively. They can help save you time and money by improving efficiency and minimizing the need for manual labor. What's more, the high-pressure pumps are constructed to be long lasting so you can enjoy consistent quality performance for the life of your vehicles. A high pressure pump is a worthwhile investment for anyone who needs to move liquids faster and more efficiently.